CTX beta 800 4A

CTX beta 800 4A

TWIN结构的紧凑型高产出4轴完整加工的生产型车削加工中心

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

CTX beta 800 4A是TWIN结构的紧凑型高生产力车削加工中心,可完成棒料,轴件和盘件的4轴完整加工。这个全新车削加工中心开拓了中型工件4轴生产型车削新领域。开创性的整机结构,液冷主轴和副主轴,选配带Y轴和TRIFIX®高精度接口的直接驱动刀塔和专利技术的TWIN机床结构以及副主轴 / 尾座复合运动还有易于操作的Siemens数控系统840D solutionline带ShopTurn 3G软件,这些特性使该机性能与该类产品的上一代产品高20%。而且占地少。

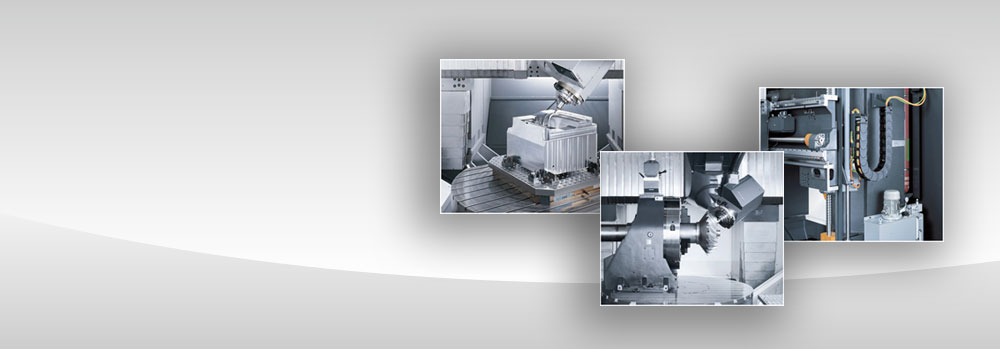

Highlights CTX beta 800 4A

- 主轴和副主轴采用水冷主轴电机

- 2 × 12位VDI 40直接驱动刀塔,最高转速:10,000 rpm,金属切除速度快(选配)

- 两个下刀塔的Y轴(上刀塔±60 mm,下刀塔±40 mm)(选配),实现棒料,轴件和盘件的完整加工。

- TRIFIX©精密刀具接口的刀塔,刀具装夹速度快,工作稳定和刀具精度高

- 专利技术的副主轴/尾座横向复合运动,更灵活使用加工区。举例:4轴加工和主轴支撑或主轴与副主轴(选配)同时加工

- 加工时间短,最高快移速度45 m/min

- 编程速度快和易于编程的Siemens ShopTurn 3G

- 稳定性好,精度保持好,结构刚性好,45号导轨

- 智能化运送系统

.jpg)

.jpg)

.jpg)

HORN / Walter刀具套件

高性能套件,包括外圆和内圆车刀,径向和轴向冲孔刀,以及螺纹刀和钻孔刀。

技术参数

CTX beta 800 4A

|

机床型号 |

|

|

CTX beta 800 4A |

|

加工区 |

|

|

|

|

Swing diameter, max. |

mm |

540 |

|

|

Turning diameter, max. |

mm |

340 |

|

|

Distance between the spindle and the tail stock (without feed) |

mm |

- |

|

|

Max. work piece length with a tailstock (can be machined) |

mm |

- |

|

|

Distance from the main spindle to the counter spindle (without feed) |

mm |

1,050 |

|

|

Max. work piece length on the counter spindle (can be machined) |

mm |

735 |

|

|

Main spindle |

|

|

|

|

Integrated motor spindle (ISM) with a C-axis (0,001°) |

rpm |

5,000 (ISM 76 synchro) |

|

|

驱动功率(40% / 100% DC) |

kW |

32 / 25 |

|

|

扭矩(40/100% DC) |

Nm |

360 / 280 |

|

|

Spindle head (flat flange) |

mm |

170 h5 |

|

|

Spindle diameter in the front bearing |

mm |

130 |

|

|

Clamping tube inner diameter |

mm |

67 |

|

|

Max. collet chuck diameter* |

mm |

250 |

|

|

Counter spindle* |

|

|

|

|

Integrated motor spindle (ISM) with a C-axis (0,001°) |

rpm |

5,000 (ISM 76 synchro) |

|

|

驱动功率(40% / 100% DC) |

kW |

32 / 25 |

|

|

扭矩(40/100% DC) |

Nm |

360 / 280 |

|

|

Spindle head (flat flange) |

mm |

170 h5 |

|

|

Spindle diameter in the front bearing |

mm |

130 |

|

|

Clamping tube inner diameter |

mm |

67 |

|

|

Max. collet chuck diameter* |

mm |

250 |

|

|

Turret (standard) |

|

|

|

|

Tool holder according to VDI / DIN 69880 |

mm |

12 x VDI 40 with TRIFIX® |

|

|

Number of driven tools / Max. speed |

rpm |

12 / 4,000 |

|

|

Drive power / Torque (40%) |

kW // Nm |

11.3 / 28 |

|

|

Switching time, 30° |

Sec. |

0.4 |

|

|

刀塔滑座(上) |

|

|

|

|

X/Y/Z轴 |

mm |

300 / ±60 / 800 |

|

|

快移速度X/Y/Z轴 |

m/min |

30 / 21.2 / 45 |

|

|

进给力 (X/Y/Z) |

kN |

5 / 4.5 / 5 |

|

|

刀塔滑座(下) |

|

|

|

|

X / Y* / Z |

mm |

195 / ±40* / 780 |

|

|

Rapid traverse speed in X / Y* / Z |

m/min |

30 / 30 / 45 |

|

|

Feed force in X / Y* / Z |

kN |

9 / 9 / 9 |

|

|

副主轴刀架 |

|

|

|

|

X* / Z |

mm |

180* / 780 |

|

|

Rapid traverse speed in X* / Z |

m/min |

25 / 45 |

|

|

Feed force in X* / Z |

kN |

9 / 9 |

|

|

尾座** |

|

|

|

|

Stroke |

mm |

300 |

|

|

力 |

kN |

6.3 |

|

|

Centre location |

MT |

5 |

|

|

|

|

||

|

机床重量 |

kg |

13,500 |

* Optional

控制系统 |

|

CELOS® - 兼容,统一,一致。 |

|

DMG MORI ERGOline®控制面板带ShopTurn 3G的Siemens 840D solutionline | Operate - 独有多通道编程系统 |